Our Technology

Double mold

Double mold is a molding method that integrates two different resins or colors. This method can create transparent and shaded portions with one mold and can create letters using just mold. Additionally, production cost can be reduced by molding two parts with only one part.

Creating letters and patterns

We can create letters and patterns without decoration, and we can make it so these parts will not fade.

Light shielding buttons

Light shielding parts can shield light from light sources for other applications and can reduce light leakage and decrease the number of necessary components.

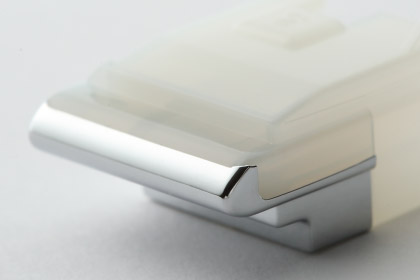

Partially plated parts

High-precision masking based on wet plating is made possible by molding plated portions with polycarbonate.

Soft resin integrated with hard resin

Combining elastomer (soft resin) and hard resin can strengthen joints and add sealing performance.

Plating colors

Supports plating colors. Chromium plating: Features a silver color with pale mirror gloss. Satin plating: Features a luxurious matte pearskin finish. We also support black trivalent chromate for each color that adds a black tone. Coating after plating will make it possible to maintain a metallic touch for coloring.

- ①

- ②

- ③

- ④

- ⑤

- ⑥

- ⑦

- ①Gloss chromium plating

- ②Satin chromium plating

- ③Gloss black trivalent chromium plating

- ④Satin black trivalent chromium plating

- ⑤Gloss chromium plating + coating (Black)

- ⑥Gloss chromium plating + coating (Champaign gold)

- ⑦Gloss chromium plating + coating (Blue)

Automation

We are incorporating automated equipment into each process as is necessary. Automation enables us to save labor, conduct high-cycle production, and deliver products with stable quality to customers.

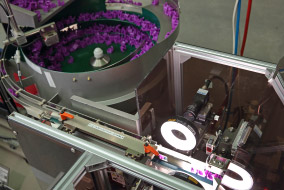

Automatic alignment

Automatic alignment of products fetched after molding for packaging reduces the load on post-process.

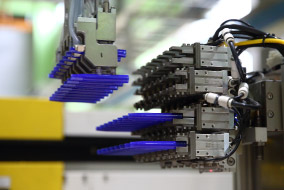

Handling robots

Handling robots are incorporated into the coating process of detaching products, which contributes to saving labor.

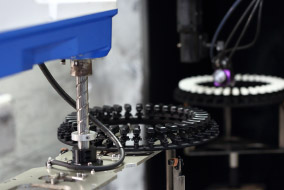

Feeding robots

Feeding robots can take out products in the laser processing step. This reduces the number of processes that require manpower and enhances productivity.

Automatic assembly

Lines are automated as necessary, which enhances quality and productivity.

Automatic inspection system

The camera-based automatic inspection system checks the size and shape of all products to assure their quality.

Quality assurance, inspections, and production control

Our in-house production control system centralizes records of production conditions, inspection records, and stock management. With this system, we immediately store every history and record during production and inspection, which helps us to analyze data for future improvements.

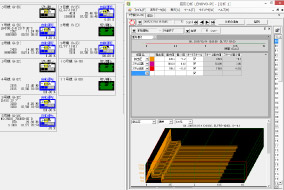

System management based on process monitoring

Our management system records various daily records from all the molders and machines that are used for production. This enables us to monitor the molding process and helps us to analyze data, especially when a malfunction occurs.

Inspection management system

We use our in-house inspection management system to implement automatic data collection and alarms. This organizes our framework and allows us to focus on our inspection process.

Order-based shipment system

We obtain order data electronically by using our in-house production control system so that we can control excessive inventory and meet customers’ various order needs and requests.