About Electroforming

Electroforming is a method to create the reverse of a master model by thick plating the surface of the master model and exfoliating it from the master model. This method uses electrochemical reactions in the same way as electroplating.

Electroforming fabrication

Master model

Product

Special features of electroforming

Superior transferability, high dimensional precision

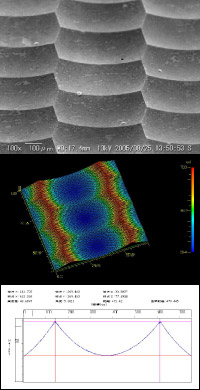

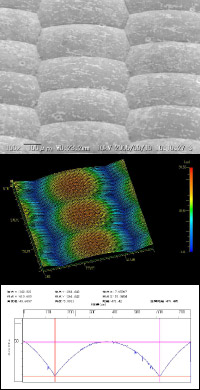

Comparison of transfer precision for micro lens array electroforming

Electroforming fabrication

Master model

Depth: 43.69 μm

Electroforming mold

Depth: 43.69 μm

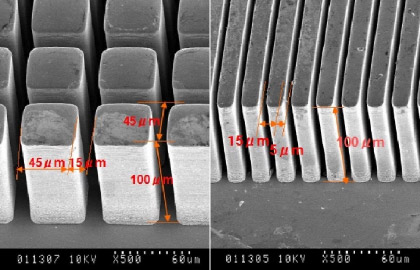

Fabricating nano-structure of fine-pitch/high-aspect ratio

Electroforming mold reversing the microscopic pattern model

Electrodeposited metal may be adjusted for physical properties, e.g., hardness and tensile strength, as well as chemical properties, e.g., corrosion resistance, according to its specific use.

Properties of electroformed nickel

| Ni | Ni-25%Co | |

|---|---|---|

| Hardness(Hv) | 200〜250 | 450〜500 |

| Tensile strength(MPa) | 550〜570 | 1300〜1500 |

| Elongation(%) | 17〜20 | 0.5〜1.5 |

| Young’s modulus(GPa) | 185 | 192 |

| Thermal expansion coefficient(×10-6/k) | 12.5〜13.0 | 11.0〜11.5 |

| Thermal conductivity(W/mK) | 90.5 |

Materials for the master may be selected according to its use.

Non-metallic master model

- Epoxy resin

- Acrylic resin

- Silicon wafer, glass

- Formed parts (ABS resin)

Electroforming manufacturing steps

Emboss processing

Silicon inversion model

Master model

Electroforming fabrication

Ni mold

Any shapes and sizes of products can be produced by electroforming bath.

Large electroforming apparatus with a capacity of 60,000 liters

An electroforming bath is installed in Class 10000 clean room to manufacture high-quality products.