Our Technology

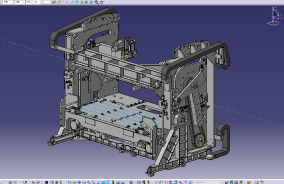

Mold design

Aiming to produce high-quality mold that exceeds customer expectations and prompt turnaround that works closely with the field. Aiming to operate efficiently and effectively by constantly looking for ways for improvement and carrying out production operations that keep customers’ needs in mind.

Electroforming processing technology

Products with complicated designs and resin products that excel in design can be manufactured. Electroforming cavity can also be used for general injection molding parts.

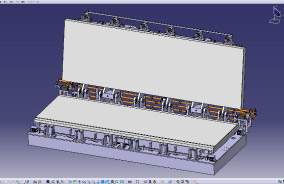

Machine processing

We take high-speed, high-accuracy, and high-efficiency as our priorities, and we look for ways to attain processing technology that can adapt to any complicated shape.

Table size: L8000 × W3750 (mm)

Expertise manufacturing technology

Finishing process of mold. We work carefully and promptly. Through the assembly process, all of the workmanship, technology, and experiences come into play in determining mold quality. We strive to advance and achieve better technology each day. Prompt service for mold repairs/building up/modification. Aiming to provide high-quality and low-cost production of new molds.

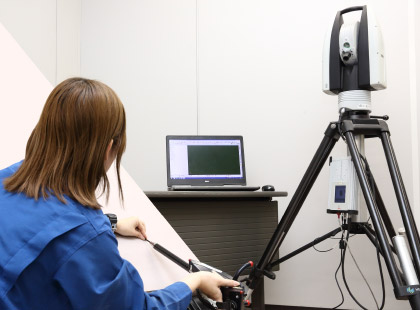

Quality assurance

We carry out numerical control to make sure defective products, from wooden models to molds, are prevented from being shipped.